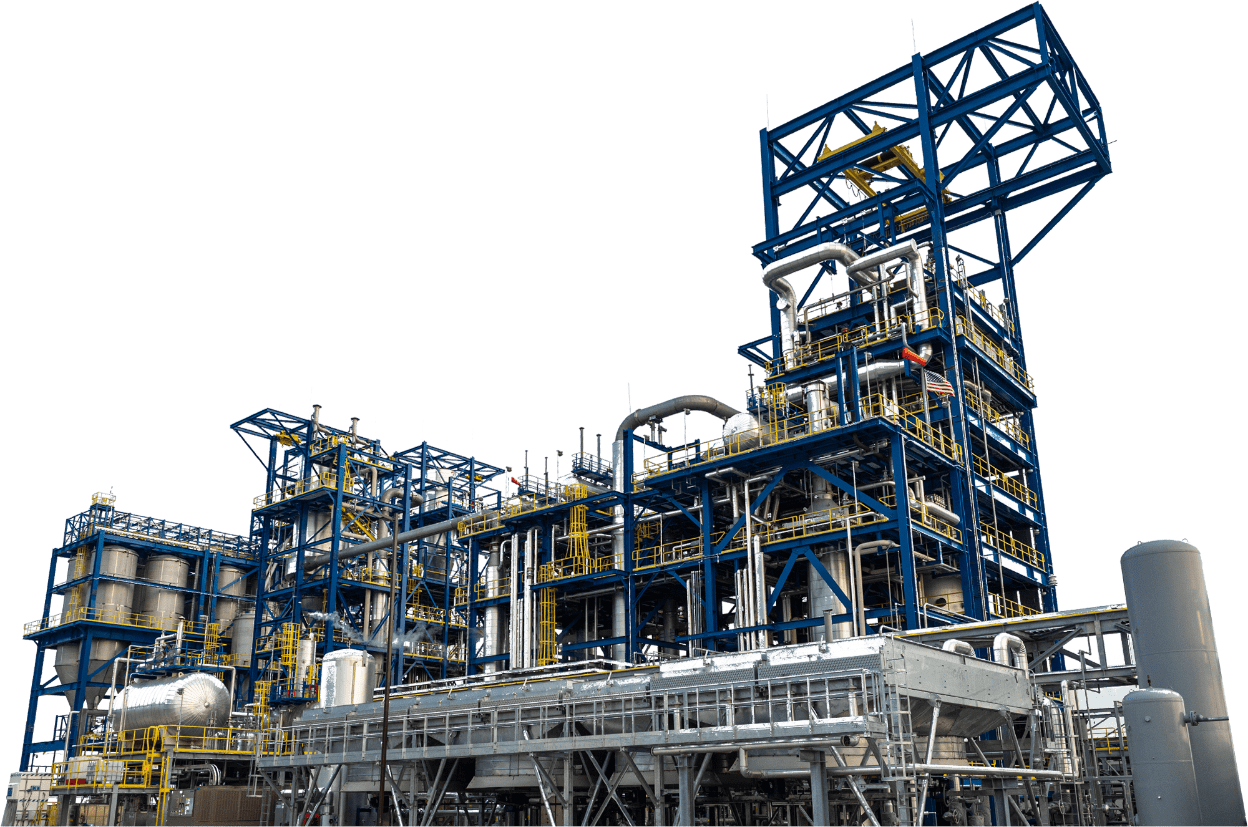

The Monolith Process

Through its proprietary technology, Monolith has innovated methane pyrolysis, which uses 100% renewable electricity to convert traditional or renewable natural gas or renewable biogas into clean hydrogen and carbon (for use in clean carbon black). This clean, sustainable process produces virtually no scope 1 emissions and significantly reduces life-cycle emissions.

Natural gas feedstock enters here.

A process gas can be added to help heat the natural gas.

The natural gas is super-heated by electricity. This is combustion-free and CO2-free.

The heat breaks the bonds between the hydrogen and carbon in the natural gas molecule.

The pairs of hydrogen atoms and carbon atoms move through the chamber and exit separately.

From here, the clean hydrogen is directed to end users, including conversion to carbon-free ammonia. The carbon is further processed into clean carbon black and other uses.